MTD

Series Membrane Check Valve Fine Bubble Diffusers

The

MTD Series Membrane Check Valve Fine Bubble Diffuser was developed for

use in applications which require fine bubble dispersion in aeration systems

which may be cycling on and off. These installations require the integral

check valve capabilities found in MTD Series Membrane Diffuser. This design

feature prevents the back flow of water when the diffuser is not aerating.

Due to its self sealing configuration using a flexible membrane, these

types of diffusers are less susceptible to clogging due to solids or biological

fouling. Since the membrane expands and contracts when it is aerating

and not aerating, there is less opportunity for organism growth on the

surface of the diffuser. The membrane diffuser provides more bubble producing

orifices on its surface area than comparable diffusers. The MTD Series

Membrane Fine Bubble Diffuser is capable of delivering flow ranges up

to 12 CFM.

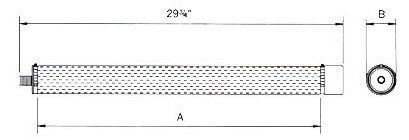

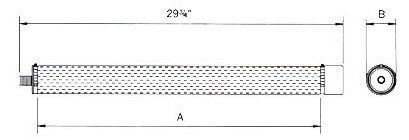

The operating principle of the Membrane Fine Bubble Diffuser is based

on raising slightly the air pressure within the membrane tube which opens

the diffuser orifices. This horizontal diffuser consists of a rigid cylindrical

plenum tube with 1/8” gas distribution slots located inline on the bottom

side of the tube. The plenum chamber is covered with a flexible membrane

sleeve made of EDPM elastomeric material. This tubular membrane has a

tight pattern of extremely small, self-sealing perforations throughout

its entire surface except for a solid band running the length of the tube.

This band is located over the air diffusion slots of the plenum chamber.

When the gas is not flowing through the diffuser, the membrane fits tightly

over the tubular plenum chamber. Since the portion of the membrane which

is not perforated is located over the distribution slots, it effectively

seals any backflow of liquid back into the diffuser when it is not pressurized.

|

| When

gas is flowing, the perforated membrane becomes extended, expanding

away from the previously sealed air diffusion slots and allowing

gas to flow freely beneath the surface of the membrane. The expansion

of this membrane sleeve opens the tightly perforated holes very

slightly and allows the gas to escape in the form of fine bubbles.

The bubbles coming from the diffuser’s surface area create a curtain

of gas its entire length. When the flow of gas is stopped the membrane

contracts, sealing the distribution slots and closing |

the

perforations in the membrane. The Membrane Check Valve Diffusers

are affixed to the distribution header with a 3/4” NPT stainless

steel nipple which allows for easy installation at new and existing

plants.

Typical applications for the MTD Series Membrane Check Valve Diffuser

include:

- pre-aeration

- aeration

- post-aeration

- nitrification

- lagoons

- aquaculture

|

|

|

The MTD Series Diffuser provides more bubble

producing orifices on its surface than comparable diffusers. It

delivers flow ranges up to 12 CFM.

|

|

|

|