DP

and DS Series

Hydro-Chek Downflow

Coarse Bubble Diffusers

Hydro-Chek

Coarse Bubble Diffusers are the result of years of extensive research

and development. They combine a simplicity of design with quality construction

to provide efficient, economical, trouble-free continuous gas diffusion.

The DP Series diffuser utilizes plastic for the diffuser body while the

DS Series is constructed of stainless steel.

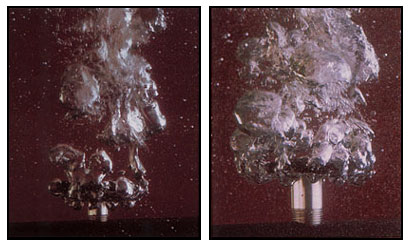

The Hydro-Chek Diffuser has a patented “downflow” mushroom-shaped design.

It utilizes a simple circular pattern of orifices to produce coarse bubbles

which take the form of a plume when the bubbles are discharged. The bubbles

then pass through the liquid and rise to the surface in a constant stream

providing gas transfer. A flexible diaphragm is positioned over the top

of the entire diffuser covering the orifices. The diaphragm of the diffuser

becomes extended when gas is flowing - thus allowing it to flow from the

orifices and form coarse bubbles. The diaphragm is held in place over

the orifices on the diffuser body with two piece locking retainer ring.

When gas is not flowing, the diaphragm retracts and seats itself over

the orifices with pressure generated from liquid in the aeration tank.

This design feature acts as a check valve when the diffuser is not aerating.

Thus the backflow of liquid to the gas distribution system is prevented.

The downflow design on the Hydro-Chek Diffuser eliminates problems associated

with sediment formation in the orifices. Particulate matter will settle

away from the diffuser because of the downflow configuration - thus minimizing

the chances of clogging. It also maximizes the shearing effect on the

bubbles as they emerge from the orifices and float upward away from the

perimeter of the diffuser forming a plume around the diffuser. These diffusers

operate effectively at a wide range of air flows up to 12 CFM.

|

| Orifices

which are located in the flexible diaphragm on some competitive

models are subject to performance robbing strains, fatigue, and

ultimately failure. The orifices of the Hydro-Chek Diffuser are

located in the rigid structure of the diffuser body elimination

this problem. The Hydro-Chek Diffuser bodies are available in the

two materials of construction - molded plastic and stainless steel.

The DP Series diffuser body is made of molded acetal plastic which

is impact resistant and non-corroding. It resists fouling by algae

or other foreign materials. For use in hostile environments, the

DS Series of diffuser bodies are constructed of type 304 or 316

series stainless steel. Not only do they provide outstanding durability,

but they are resistant to chemical attack. The diffuser bodies are

available with 3/8” or 3/4” NPT threads, depending on model and

size. |

The

air check diaphragm of the diffuser is molded of an EPDM elastomeric

which is flexible, resilient and resists both fatigue and chemical

attack. Because of its excellent flexibility characteristics it

provides positive sealing action when the diffuser is not operating.

Typical applications for the Hydro-Chek Coarse Bubble Diffuser

include:

- pre-aeration

and aeration chambers

- digesters

- channels

- package

wastewater treatment plants

- post-aeration

structures

- sludge

holding tanks

- low

pressure equalization applications

- check

value blow off pipes on aeration system

|

|

|

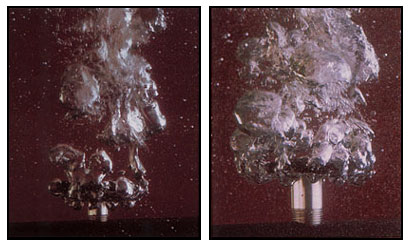

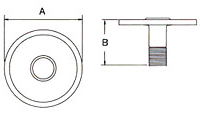

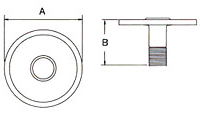

The DS-38 diffuser (left) provides a flow

range of .5 to 3 CFM,

while on the right, the DS-75 produces a 3 to 12 CFM range.

|

|

|